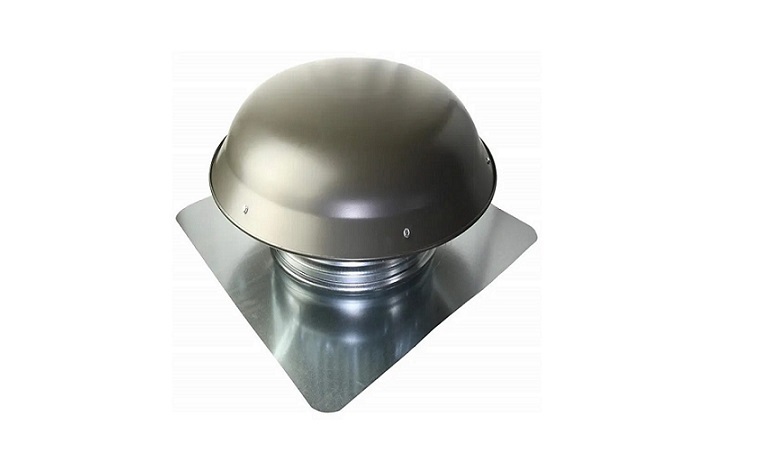

Common problems and solutions of Ventilation shell

Release time:

2025-01-09

Common problems manufacturers often encounter and traditional solutions in the production process are as follows:

First of all, the phenomenon of cracks or fractures on ventilation equipment parts is often caused casting, processing defects or internal stress, and overload operation.The conventional repairing method is to use welding, but welding often leads to thermal deformation or thermal stress in parts, especially thin-walled parts.Some parts are made of cast iron, aluminum alloy, titanium alloy and a class of refractory materials. There are also some occasions prone to explosion risk, such as the petrochemical industry, etc. It is not easy to use welding repairing method, which seriously limits the maintenance level of equipment, and increases the operating costs of enterprises.

Secondly, most of the equipment parts are metal, Deformation occurres because of its high strength with high hardness, Material recovery stress drop, then leave a gap, which can not meet the operation requirements, resulting in wear and tear of transmission components. The traditional repair methods include overlaying welding, thermal spraying, brush plating and so on.

The last problem is the corrosion of the shell under the complicate environment changes in long time. It will not only cause economic losses for enterprises, but also have a certain harm to safety and the environment of the factory. Therefore, frequent replacement of equipment parts is the current temporary method taken by enterprises. And the components are limited by materials and processing technology, with high cost.

Look forward to common development

Lumaker has been dedicated to provide expert precision sheet metal fabricating services to customers all over the world.

Get a Quote